A Lab-Tested Wake-Up Call: The Hidden Costs of Cheap Drawer Slides

Earlier this year, a showed a tool cabinet crashing mid-use due to weak drawer slides. While , it reflects a daily frustration for many—drawer slides that can't handle the load. In commercial kitchens, workshops, and high-use household areas, failure isn't an option.

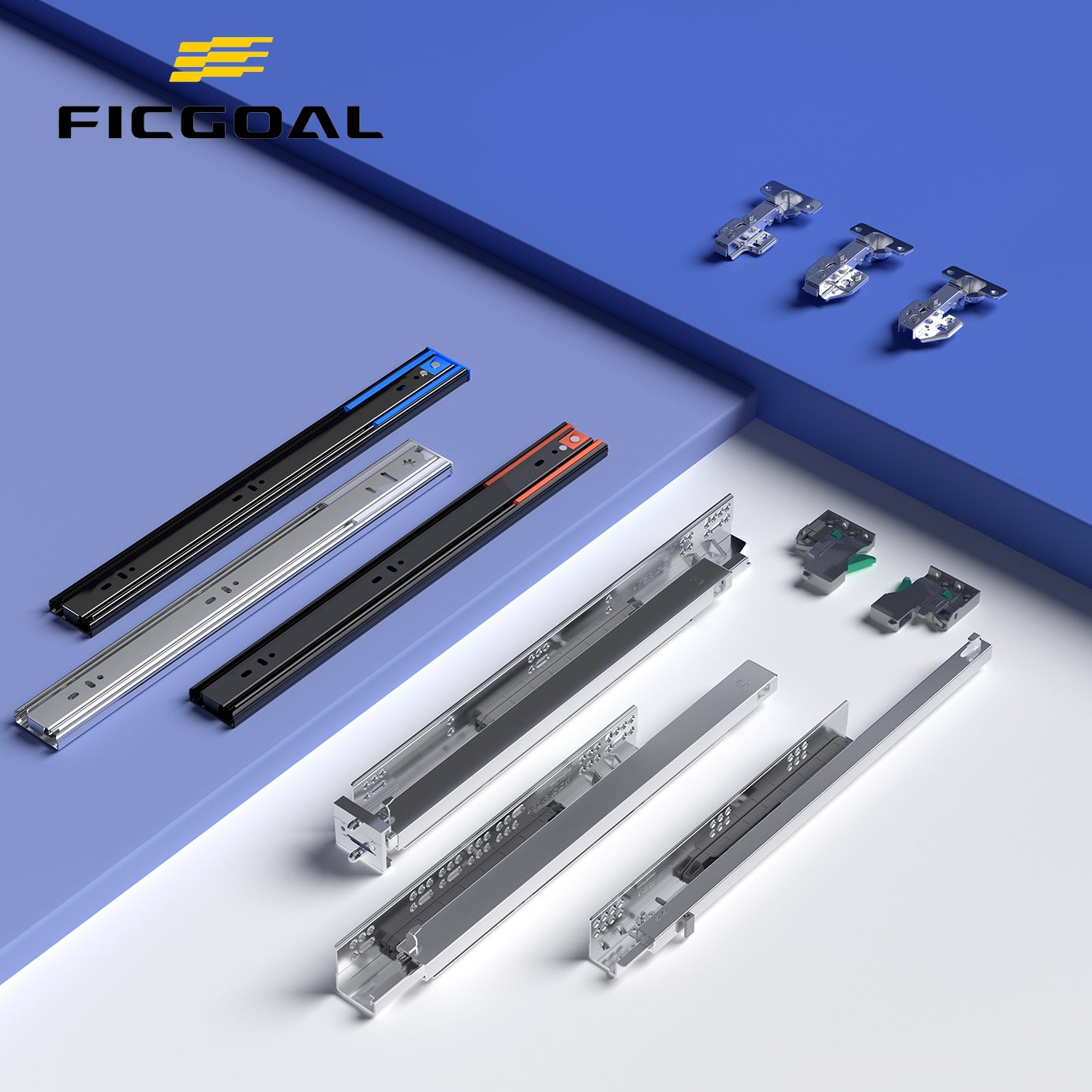

Ficgoal Drawer Slides aim to solve that with durability, soft-close precision, and 50 kg load capacity .

What Are Ficgoal Drawer Slides? Built for Weight. Designed for Silence.

Ficgoal Drawer Slides are full-extension, soft-close sliding rails crafted from cold-rolled steel, designed to handle daily wear and tear in demanding environments.

Feature | Ficgoal Model X200 | Market Average |

Load Capacity | 31–50 kg (68–110 lbs) | 100–150 lbs |

Material | Cold-rolled steel with zinc or powder coating | General steel alloy |

Extension Type | 100% full-extension | 75–90% extension |

Closing Mechanism | Soft-close with hydraulic damper | Standard metal stop |

Lifecycle (Tested Pulls) | 100,000 pulls (Ficgoal internal test data) | 30,000–50,000 pulls |

Why Drawer Slides Fail—and How Ficgoal Prevents It

Most users don’t realize that drawer slide failure is rarely about wear—it's about underengineering:

❌Weak rollers wear out under load

❌ Low-grade steel bends over time

❌No dampers = slamming drawers and shortened life span2025

That’s where Ficgoal Drawer Slides come in—built to hold 50 kg, close , and resist corrosion.

Inside Ficgoal's Drawer Slides: The Core Tech That Matters

Dual Ball-Bearing Tracks: For consistent, low-friction movement even under full load.

Triple-Layer Anti-Corrosion Coating: Salt spray tested for 48–72 hours (typical zinc-coated steel rating)—ideal for , kitchen, or garage use.

Integrated Damper Technology: A hydraulic piston absorbs closing shock, ensuring both drawer protection .

Installation Guide: Ficgoal Slides Make It Easy

Installing Ficgoal Drawer Slides doesn’t require professional help—just a screwdriver and level.

Step-by-Step:

1. Mark cabinet and drawer alignment lines.

2. Screw cabinet member onto the side panel.

3. Fix drawer member on drawer sides using pre-marked holes.

4. Snap together and test for level & smoothness.

Industry Insight: Why 2025 Is the Year for Heavy-Duty Upgrades

According to a 2025 survey by HomeBuilder Insights, over 73% of kitchen contractors are 100+ lb drawer slides due to increased drawer size and load.

At the same time, search volume for “heavy duty drawer slides” has surged by 28% YoY, with niches like “undermount drawer slides for tool chests” driving specialized demand.

Choose the Right Model: Ficgoal’s Drawer Slides Lineup

Model | Lengths (in) | Load Capacity | 31–50 kg (68–110 lbs) |

X200HD | 12–28 | 50 kg | Full Extension, Soft Close |

X150SM | 10–24 | 40 kg | Smooth Glide, Standard Close |

X100SS | 12–20 | 35 kg | Stainless Steel, Marine Safe |

Conclusion: Are Your Drawer Slides Still Failing?

With heavy-duty demands rising across industries, underperforming slides are a hidden liability.

Ficgoal Drawer Slides —perfect for those who .

Whether you're upgrading your workshop drawer systems, outfitting a custom kitchen, or supplying an entire OEM cabinet line, Ficgoal is the .

Contact us today to explore your best-fit sliding solution.